Router Shaker Cabinet Door Styles and Designs

Shaker cabinet doors, known for their clean lines and simple elegance, offer a timeless appeal in any kitchen or home setting. The versatility of the shaker style, combined with the precision of a router, allows for a wide range of customized designs. This exploration delves into the various styles achievable, the router bits involved, and the aesthetic impact of wood choices and finishes.

Shaker Cabinet Door Styles and Their Defining Characteristics

Shaker cabinet doors are characterized by a recessed central panel framed by a raised outer frame. Variations arise from the profile of the frame and panel, and the detailing applied. Common styles include the raised panel shaker, the flat panel shaker, and variations with beaded or ogee edges. The raised panel shaker features a raised central panel, while the flat panel shaker has a flush panel. Beaded and ogee edges add decorative flourishes to the frame. These variations allow for a diverse range of aesthetics, from traditional to contemporary.

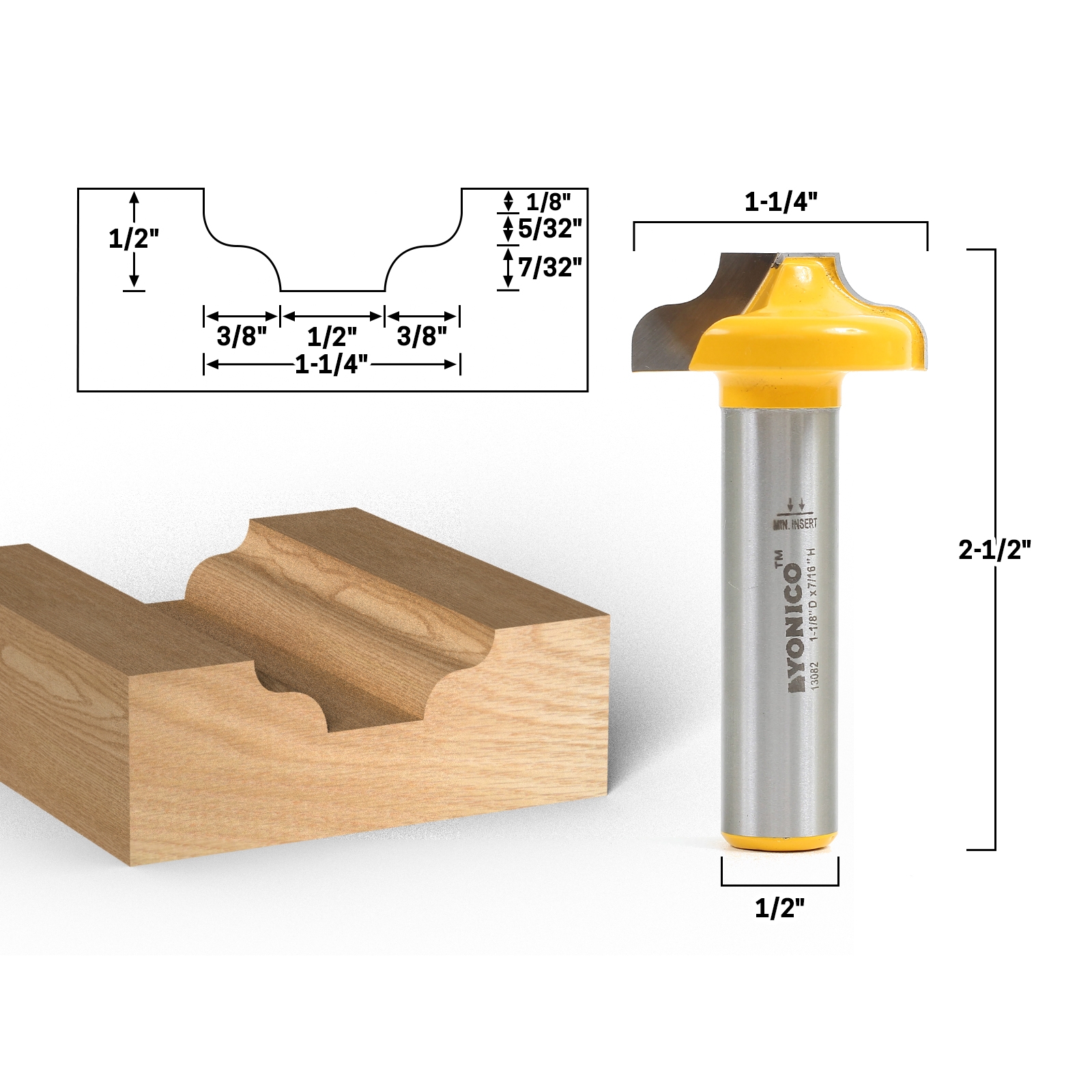

Router Bits for Creating Shaker Door Profiles

Different router bits are crucial in achieving the desired shaker door profile. A straight bit is used to create the basic frame and panel grooves. A cove bit creates a concave profile on the frame’s edge, adding a softer, more elegant look. An ogee bit creates a more complex S-shaped profile, offering a more ornate and traditional feel. A Roman ogee bit creates a variation on the ogee with a sharper transition between curves. The cutting process typically involves multiple passes, ensuring precise cuts and clean edges. For example, creating a raised panel requires routing the panel recess first, then routing the frame’s edges to create the raised effect. Incorrect depth of cut can result in a damaged door, requiring careful attention to router bit depth settings.

Aesthetic Impact of Wood Types and Finishes

The choice of wood significantly influences the overall aesthetic of a shaker cabinet door. Hardwoods like cherry, maple, and walnut offer durability and rich color variations. Softwoods like pine provide a more rustic, affordable alternative. The wood’s grain pattern also plays a role, with straight grains lending a clean, modern feel, while more pronounced grain patterns add character and visual interest. Finishes such as paint, stain, or varnish further impact the final look. Paint provides a uniform, modern look, while stain enhances the wood’s natural beauty. Varnish protects the wood and provides a glossy or matte finish, depending on the type used. For instance, a painted white shaker door in maple creates a clean, contemporary feel, while a stained cherry shaker door with a clear varnish showcases the wood’s rich tones and grain.

Examples of Unique Shaker Cabinet Door Designs

The following table illustrates three unique shaker cabinet door designs, showcasing different router bit combinations and wood types. Each design offers a distinct aesthetic, demonstrating the versatility of the shaker style.

| Design | Wood Type | Router Bits Used | Description |

|---|---|---|---|

| Design 1 | Maple | Straight bit, cove bit | Clean lines, simple cove profile on the frame, creating a modern, minimalist aesthetic. The light color of the maple enhances the clean lines. |

| Design 2 | Walnut | Straight bit, ogee bit | Rich dark color of walnut contrasted with the elegant curves of the ogee profile, creating a traditional, sophisticated look. The ogee bit adds a touch of ornate detail. |

| Design 3 | Pine | Straight bit, Roman ogee bit | Rustic charm of pine combined with the more pronounced curves of the Roman ogee bit, resulting in a slightly more dramatic and detailed design. The natural variations in the pine grain add character. |

Building Router Shaker Cabinet Doors

Constructing shaker-style cabinet doors using a router offers a blend of elegance and efficiency. The clean lines and simple design of shaker doors make them a popular choice for kitchens and bathrooms, and the precision of a router allows for consistent, high-quality results. This guide details the process, emphasizing accuracy and providing techniques for successful door construction.

Preparing the Wood and Cutting the Frame Pieces, Router shaker cabinet doors

Accurate measurements are paramount in woodworking. Even slight discrepancies can lead to misaligned joints and an unprofessional finish. Begin by carefully measuring the desired dimensions of your cabinet door. For this example, let’s assume a final door size of 12 inches wide by 18 inches tall. Remember to account for the thickness of the frame pieces and panel when determining the dimensions of the individual components. Using a high-quality tape measure and marking gauge ensures precision. To mitigate errors, double-check all measurements before cutting. A good practice is to mark the wood twice, ensuring the markings align perfectly. Then, use a sharp blade in your miter saw or table saw to make precise cuts. This minimizes tear-out and ensures clean, straight edges.

Creating the Raised Panel

The raised panel is a defining feature of the shaker style. The panel’s size should be slightly smaller than the interior dimensions of the frame to allow for a snug fit. For our 12″ x 18″ door, a panel size of approximately 11.5″ x 17.5″ would be suitable, depending on the thickness of the frame. Again, precise measurement is crucial. The panel can be created from a single piece of wood, or multiple pieces can be joined using techniques such as biscuits or dowels for added strength. Once the panel is cut to size, use a router with a raised panel bit to create the raised profile. Clamp the panel securely to your workbench and use a slow, steady feed rate to avoid tear-out. Consistent depth and speed are vital for an even, symmetrical raised panel.

Assembling the Door Frame and Panel

Several joinery methods can be used to assemble the frame and panel. Pocket hole joinery is a popular choice for its strength and ease of use. It involves drilling angled holes at the ends of the frame pieces, allowing for screws to be inserted without being visible on the surface. Alternatively, dado joints can provide a strong and visually appealing connection. Dado joints are created by cutting recesses in the frame pieces to accommodate the panel’s edges. For a more advanced approach, mortise and tenon joints offer exceptional strength and a clean, traditional look. Regardless of the chosen method, ensuring precise alignment is key. Use clamps to hold the pieces together securely while the glue dries.

Step-by-Step Guide with Image Descriptions

- Step 1: Cutting the Frame Pieces. Image: A detailed close-up showing accurately measured and marked wood pieces, ready for cutting with a miter saw. The image highlights the clean, precise cuts and the use of a measuring tape and marking gauge for accuracy.

- Step 2: Cutting the Panel. Image: A depiction of a piece of wood being cut to the precise dimensions of the panel using a table saw. The image emphasizes the use of a push stick for safety and the clean, square cut resulting from a sharp blade.

- Step 3: Routing the Raised Panel. Image: A close-up shot of a router with a raised panel bit being used to create the raised profile on the panel. The image showcases the steady and controlled movement of the router, ensuring an even profile. The clamped-down panel and safety precautions are also highlighted.

- Step 4: Creating the Joints (Example: Pocket Holes). Image: A clear view of pocket holes being drilled into the ends of the frame pieces using a pocket hole jig. The image illustrates the precise angle of the holes and the use of a drill press for consistency.

- Step 5: Assembling the Frame. Image: The frame pieces are shown carefully assembled and clamped together, showcasing the accurate alignment and secure fit of the pocket holes. Wood glue is visible in the joints.

- Step 6: Inserting the Panel. Image: The raised panel is shown being carefully inserted into the assembled frame. The snug fit and the accurate dimensions of the panel are highlighted.

- Step 7: Securing the Panel (Example: Using Brads). Image: Small brads are shown being carefully hammered into the frame to secure the panel in place. The image highlights the placement of the brads to minimize visibility.

- Step 8: Finishing. Image: The completed shaker door is shown after sanding and finishing, highlighting the smooth surface and the clean lines of the shaker style. The image emphasizes the professional look achieved through careful craftsmanship.

Advanced Techniques and Customization Options for Router Shaker Cabinet Doors

Creating truly unique shaker cabinet doors involves mastering advanced router techniques and exploring various customization options. This section details methods for achieving complex designs, adding decorative elements, and applying diverse finishing techniques to elevate your woodworking projects.

Using Templates and Jigs for Complex Shaker Door Designs

Templates and jigs are invaluable tools for achieving consistent and precise results when routing complex shaker door profiles. Templates, typically made from durable materials like MDF or plywood, guide the router bit along a predetermined path, ensuring accuracy and repeatability. Jigs, on the other hand, provide support and stability for the workpiece during routing, minimizing the risk of tear-out and ensuring a smooth finish. For example, a simple jig can be constructed to hold multiple door panels at once for efficient batch processing. More intricate jigs might incorporate adjustable features to accommodate different door sizes and styles. Precisely cutting complex shapes, such as curved rails or stylized stiles, becomes significantly easier and more accurate with the use of appropriately designed templates and jigs. Careful planning and construction of these tools are crucial for achieving professional results.

Methods for Creating Decorative Elements on Shaker Doors

Decorative elements significantly enhance the aesthetic appeal of shaker doors. Raised panels, a classic shaker feature, add depth and visual interest. These are typically created by routing a recess into the door panel, then inserting a raised panel of contrasting wood or material. This requires careful measurement and precise routing to ensure a snug fit. Inlays offer another avenue for customization. Intricate designs can be cut into the door surface and filled with contrasting wood, metal, or other materials. This technique demands precision and often involves the use of specialized tools like inlay cutting bits and specialized jigs to hold the inlay securely in place during the gluing process. For example, a simple geometric inlay can add a modern touch, while more elaborate designs can create a truly bespoke look. The choice of decorative elements will largely depend on the overall design aesthetic and skill level of the woodworker.

Finishing Techniques for Shaker Cabinet Doors

The finishing process is crucial for protecting and enhancing the appearance of shaker cabinet doors. Painting offers a wide range of color options and provides a durable, easily cleanable surface. However, painting can sometimes obscure the wood grain. Staining, conversely, allows the natural beauty of the wood to shine through, enhancing the grain pattern with various shades and tones. However, stains can be more challenging to apply evenly and require careful preparation of the wood surface. Clear coating, using polyurethane or lacquer, protects the wood from moisture and scratches while preserving its natural appearance or enhancing the color of a stain. The choice of finishing technique depends on the desired aesthetic and the level of protection required. Each method requires careful preparation and application to achieve a professional, high-quality finish. For instance, a high-gloss polyurethane finish will give a very different look than a matte lacquer. Proper surface preparation, such as sanding and priming, is essential for any finishing method to ensure optimal adhesion and a flawless result.